Continued process verification involves collecting and analyzing facts from schedule manufacturing runs and generating vital adjustments to maintain the validated condition on the process.

Each and every manufacturing process stage is managed making sure that the finished product meets all described quality attributes.

Understand effective ways to reduce waste, streamline operations, and boost All round effectiveness inside your manufacturing plant.

Additionally, process validation plays a vital position in guaranteeing item basic safety. It helps discover probable challenges and deviations that may compromise the safety of the tip products and solutions. By addressing these pitfalls and deviations, firms can ensure that their products are Secure for individuals to employ.

By validating the process, firms might have self confidence inside the regularity and dependability of their manufacturing strategies, leading to enhanced solution high-quality, enhanced buyer satisfaction, and compliance with regulatory expectations.

Right after execution, you progress into the critique phase. Right here, you review the information gathered to ascertain In the event the process consistently produces the desired outcomes. This stage is very important for figuring out parts of improvement.

A fantastic validation procedure need to make certain that each individual phase, each individual process, check here and each improve continues to be adequately evaluated ahead of implementation. Tests a sample of the ultimate item will not equate to conclusive evidence that each of the solutions inside of a batch fulfill the specification.

Tools and platforms like SafetyCulture (previously iAuditor), a cellular initial operations platform, may help you streamline your organization’s manufacturing process according to GMP recommendations. Employing SafetyCulture’s powerful capabilities, you are able to do the following:

Stage 1 – Process Design: The professional manufacturing process is defined throughout this phase dependant on understanding obtained as a result of development and scale-up things to do.

These rules collectively be sure that GMP validation aligns with international excellent, safety, and efficacy benchmarks, safeguarding equally patient wellbeing and the pharmaceutical sector’s trustworthiness. Look at which GMP restrictions and preambles use for you and find out more.

Process validation might be categorized into four styles dependant on the stage wherever the process is getting evaluated:

Over the process style phase, it is actually important to make certain all elements of the process are comprehensively comprehended and documented. This includes not merely the technological specs but in addition the possible impression of various aspects to the process performance.

Cleansing validation guarantees the cleansing methods utilized inside here a manufacturing facility correctly get rid of residues of your active pharmaceutical elements (API), excipients, and cleansing brokers from your machines and also the natural environment.

From analyze, it might be stated that Process validation is A serious need of cGMP regulation for finished pharmaceutical goods. It is just a essential factor in assuring that the standard objectives are achieved. Productively validating a process may decrease the dependence on intensive in process and concluded merchandise tests.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Freddie Prinze Jr. Then & Now!

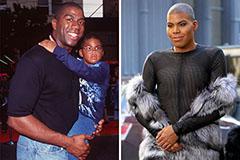

Freddie Prinze Jr. Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now!